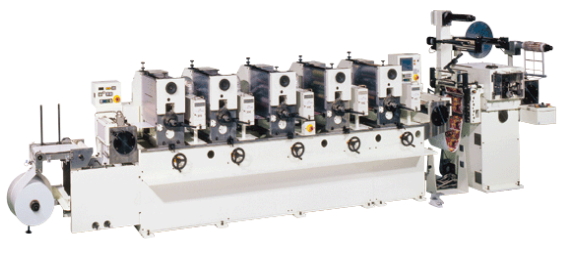

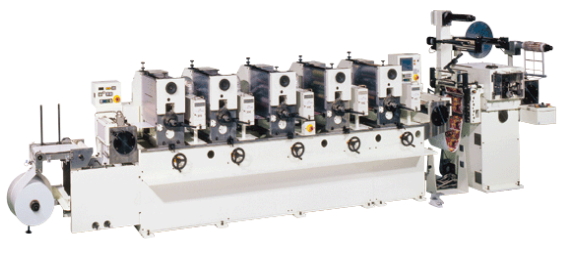

Semi-rotary Letterpress NS-250

-

NS-250 Semi-rotary Letterpress

-

Economical

Complete cost reduction by high productivity.

-

Compact

Minimized installation space and web loss by compact design.

-

High quality

Quality which is equivalent to offset printing by letterpress.

High quality printing.

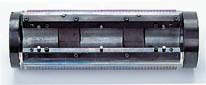

Printing roller layout calculated by computer achieves powerful ink coverage.

Three form rollers make superior result.

|  |

| Stable and accurate printing register will minimize web loss.

Twin nip rollers installed at both end of printing section keep the web tension constant through all the process.

The web proper tension can be set easily on the touch screen according to printed material. Consequently the waste of web can be reduced. |

Easy operation and shortened make ready time are suitable for large variety and small amount production.

|

All settings can be done automatically only by inputting necessary data such as printing speed, print length, cutting ratio of Flat Die and necessary options on the touch screen monitor.

Easy plate change is suitable for large variety and small amount production. |  |

| Various attachments can be added for combination printing. |

In order to satisfy changing needs of today's market, a wide range of

attachment is available as option such as flexible die which enables cutting

into complicated shapes and forms, flexo printing unit, flexo varnishing unit,

hot stamping unit, laminating device and sheet cutting unit. |

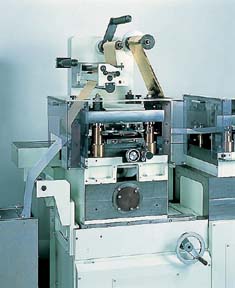

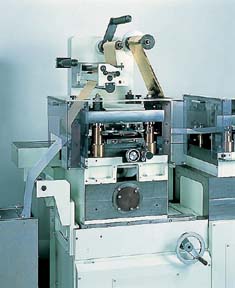

| Hot foil stamping unit is an available option. Accurate digital heat control per ± 1 degree makes it consistent regardless of the running speed. |

| Laminating device with a driving motor is an available before die cutting as an option. |  |

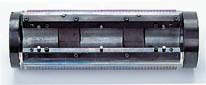

| Die-cutting is done by a flat bed die with cranks and roller bearings which makes accurate half cutting. Die-cutting register and pressure can also be adjusted whilst the machine is in operation. |

| Twisiting adustment for the plate is possible. (Option) |

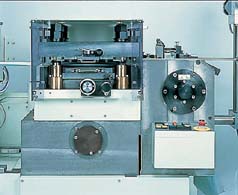

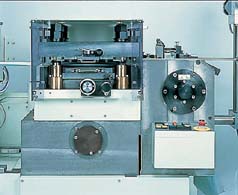

| Clamp type cylinders have greatly shortened the plate setting time and enabled make ready for plate mounting at the outside of the machine. |  |

Specifications

| Printing process | Letter press |

| Plate type | 0.95mm or other thickness by request |

| Printing process | Photo resin plate |

| Printing area (max.) (L x W) | 190 x 240 mm |

| Number of printing stations | 1~ 7 color |

| Repeat length (Length increment 0.1mm) | 10 ~ 260 mm |

| Web wideth | 50 ~250 mm (2" ~ 9.8") |

| Web roll dia. (max) | Φ400 mm |

| Operating speed | 20 ~ 210 imp/min |

| Die-cutting method | Flat die-cutting unit |

| Die cut area (max.) (L x W) | 190 X 240 mm |

| Length of cutting ratio | 2500 mm (Max. pressure 29400N) |

| Pring/die-cutting ratio | 1:1, 1:2, 1:3 |

| Machine dimensions (L x W x H) | 5654 x 1000 x 1304 mm (5 color) |

| Machine weight (approx.) | 4000 kg (5 color) |